2.5 Turn Door Handle Springs, 1.4mm Round Wire. Suitable for some Rothley Brass Handles.

Sorry, but we're not accepting orders at present. We will resume running this website later in the year.

Available in packs of 3 Left Hand Springs plus 3 Right Hand Springs or in packs of 6 Left Hand Springs plus 6 Right Hand Springs.

External diameter of coil = 21mm

Wire Diameter = 1.4mm

Side Arm length = 4mm

We offer a very similar spring made from 1.65mm wire. You may find the additional photographs help to choose between these two types.

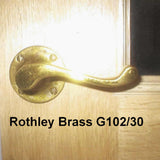

This spring is suitable for the Rothley Brass G102/30 handle - See additional picture. It may suit other Rothley Brass models too. Models RB/G 100, RB/G 101, RB/G 200, RB/G 201 take our 1.65mm spring, but please double check the wire diameter (see photo with the coils compared with a stack of 1p pieces) just to be sure.

As with any door handle spring, the spring must be pre-tensioned when the handle is horizontal. This is achieved by fitting the spring with the handle raised above the horizontal. If the handle is then lowered (winding up the spring), the cam washer should drop into place when the handle reaches the horizontal position and then keep the handle from springing up above the horizontal. The pictures for our similar 1.65mm spring may act as a guide to fitting (see separate listing).

-

Place spring in chamber, making sure the bottom arm is located in the hole in the bottom of the chamber.

-

Raise the handle to vertical.

-

Place the cam washer over the handle shaft, making sure the top arm of the spring locates into the hole in the cam washer. At this point the cam washer will not be seated properly.

-

Lower the handle down to horizontal, winding up the spring. You should feel the tension as you lower the handle.

-

Once the handle reaches the horizontal position, the cam washer should drop down so the tab on the cam washer is between the two stops that define the handle's range of movement.

-

The tab of the cam washer should be at one end of the range of movement when the handle is horizontal.

-

When the handle is pressed down from horizontal (normal operation) the tab of the cam washer will move to the other end of its permitted range of movement. This stops the handle being pressed down any further.

We Also Recommend